DC isolators are integral components in many electrical systems, designed to interrupt or isolate the flow of electric current. While they are essential for safety and functionality, there have been instances where DC isolators catch fire, posing significant risks. Understanding the reasons behind such incidents is pivotal in implementing measures to mitigate these risks.

One of the primary reasons DC isolators catch fire is due to arcing. Arcing occurs when there’s a high voltage across an isolator, causing an electric breakdown of the gases surrounding the contacts, leading to a sustained electric discharge or “arc.” This arc can generate high temperatures, causing the isolator's components to melt or catch fire, especially when the materials used are not of high quality or are not suitable for the application.

Another common factor contributing to fires in DC isolators is the accumulation of dust and debris. When isolators are not adequately sealed or maintained, dust, debris, and even insects can accumulate inside, potentially causing short circuits or overheating, which in turn can lead to fires.

Furthermore, improper installation and poor connection are significant contributors to DC isolators catching fire. When the isolators are not correctly installed or when the connections are loose, it can lead to increased resistance at the connection points. This increased resistance can cause overheating and potentially result in a fire, especially when the system is under high load.

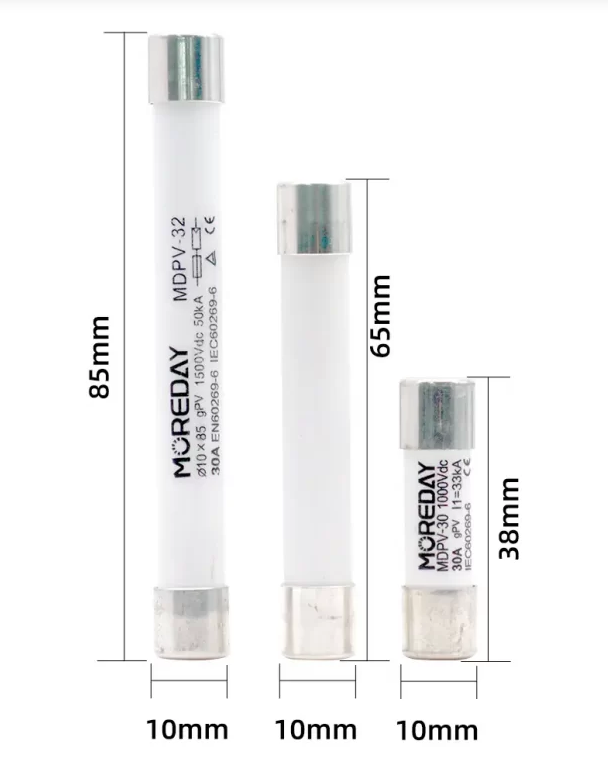

To mitigate the risk of fire, the incorporation of a DC Fuse Link is crucial. A DC Fuse Link is designed to sever the electrical circuit when an overcurrent situation occurs, thereby preventing damage to the isolator and reducing the risk of fire. Ensuring that a quality DC Fuse Link is integrated into the system is an essential step in enhancing the safety of DC isolators.

The presence of moisture and water ingress is another factor that can lead to DC isolator fires. When moisture enters the isolator, it can cause short circuits or corrosion of the components, which can ultimately result in a fire. Therefore, ensuring that DC isolators are adequately sealed and installed in locations not prone to water ingress is vital for safety.

Regular maintenance and inspection of DC isolators are also essential in preventing fires. By routinely checking the condition of the isolator, ensuring that connections are tight, and that there is no accumulation of dust or debris, the risk of fire can be significantly reduced.

Addressing the question of why DC isolators catch fire necessitates a thorough understanding of the various factors involved, from the quality of components to installation and maintenance. Implementing protective measures, such as integrating a DC Fuse Link and ensuring regular checks, are key steps in promoting the safe operation of DC isolators in electrical systems.